tech

The Revolution of 3D Printing Technology

The Revolution of 3D Printing Technology

3D printing technology, once a concept reserved for science fiction, has now made significant strides in various industries, with construction being one of the most promising fields. The integration of 3D printing in construction has opened doors to innovation, sustainability, and cost-effectiveness, revolutionizing how we think about building structures. This technology, known as additive manufacturing, is redefining architectural possibilities and reshaping the future of the construction industry.

LINK DOMAIN javanet247.com

1.3D Printing Understanding 3D Printing Technology in Construction

3D printing, also referred to as additive manufacturing, involves creating three-dimensional objects layer by layer using computer-aided design (CAD) models. In construction, this technology uses specialized machinery to print entire structures or components directly on-site or in a controlled environment. The materials used typically include concrete, polymers, and various composites, allowing for diverse applications in residential, commercial, and industrial projects.

The process begins with designing a digital model of the structure using CAD software. This model is then translated into a series of instructions that guide the 3D printer to lay down material precisely, layer by layer, until the final structure is completed. This method differs from traditional construction, which often requires molds, scaffolding, and extensive manual labor. 3D printing streamlines the construction process, reducing the need for additional tools and minimizing waste.

2. 3D Printing Advantages of 3D Printing in Construction

One of the most significant advantages of 3D printing in construction is its potential to reduce construction time dramatically. Traditional building methods are labor-intensive and time-consuming, often taking months or even years to complete a project. In contrast, 3D printing can reduce this timeline significantly, with some structures being printed in just a few days. This efficiency translates to cost savings for developers and homeowners alike.

Another advantage is the reduction in material waste. Traditional construction methods can be inefficient, leading to excess material that often ends up in landfills. 3D printing, however, uses only the material necessary for the structure, minimizing waste and contributing to more sustainable building practices. Additionally, 3D printing allows for the use of recycled materials, further enhancing its environmental benefits.

Customization is another key benefit of 3D printing technology. With traditional construction, making design changes can be costly and time-consuming. However, 3D printing offers unparalleled flexibility in design, allowing for complex and customized structures to be created with ease. This capability enables architects and designers to push the boundaries of creativity, resulting in unique and innovative buildings that were previously unimaginable.

3. 3D Printing Applications of 3D Printing in Construction

The applications of 3D printing in construction are vast and varied, with projects ranging from small-scale homes to large industrial complexes. One of the most well-known applications is the construction of affordable housing. In regions where housing shortages are prevalent, 3D printing offers a cost-effective solution. Entire communities can be built quickly and affordably, providing safe and durable homes for those in need.

In addition to affordable housing, 3D printing is also being used for the construction of emergency shelters. In disaster-stricken areas, speed is of the essence. 3D printing allows for the rapid construction of shelters that can withstand harsh conditions, providing immediate relief to affected populations.

Commercial and industrial projects are also benefiting from 3D printing technology. Complex structures, such as bridges, office buildings, and factories, can be printed with precision and efficiency. This technology is particularly advantageous in remote or challenging locations where traditional construction methods may be impractical or too costly.

4.3D Printing Challenges and Limitations

While 3D printing in construction offers numerous advantages, it is not without its challenges. One of the primary concerns is the initial cost of 3D printing equipment. The technology, although rapidly advancing, requires significant investment in machinery and software. For smaller construction companies, this upfront cost can be a barrier to adoption.

Another challenge is the limited range of materials currently available for 3D printing in construction. While concrete and polymers are commonly used, the development of new materials that offer greater strength, durability, and sustainability is ongoing. Until these materials become widely available, the application of 3D printing may be restricted to certain types of projects.

Regulatory and safety standards also pose challenges. As with any new technology, 3D printing in construction must adhere to building codes and safety regulations. However, because the technology is still relatively new, there is a lack of comprehensive standards, leading to uncertainties in its adoption and implementation.

5.3D Printing The Future of 3D Printing in Construction

Despite these challenges, the future of 3D printing in construction looks promising. The technology is expected to continue evolving, with advancements in materials, machinery, and design software driving its adoption. As costs decrease and technology becomes more accessible, 3D printing could become a standard method in the construction industry.

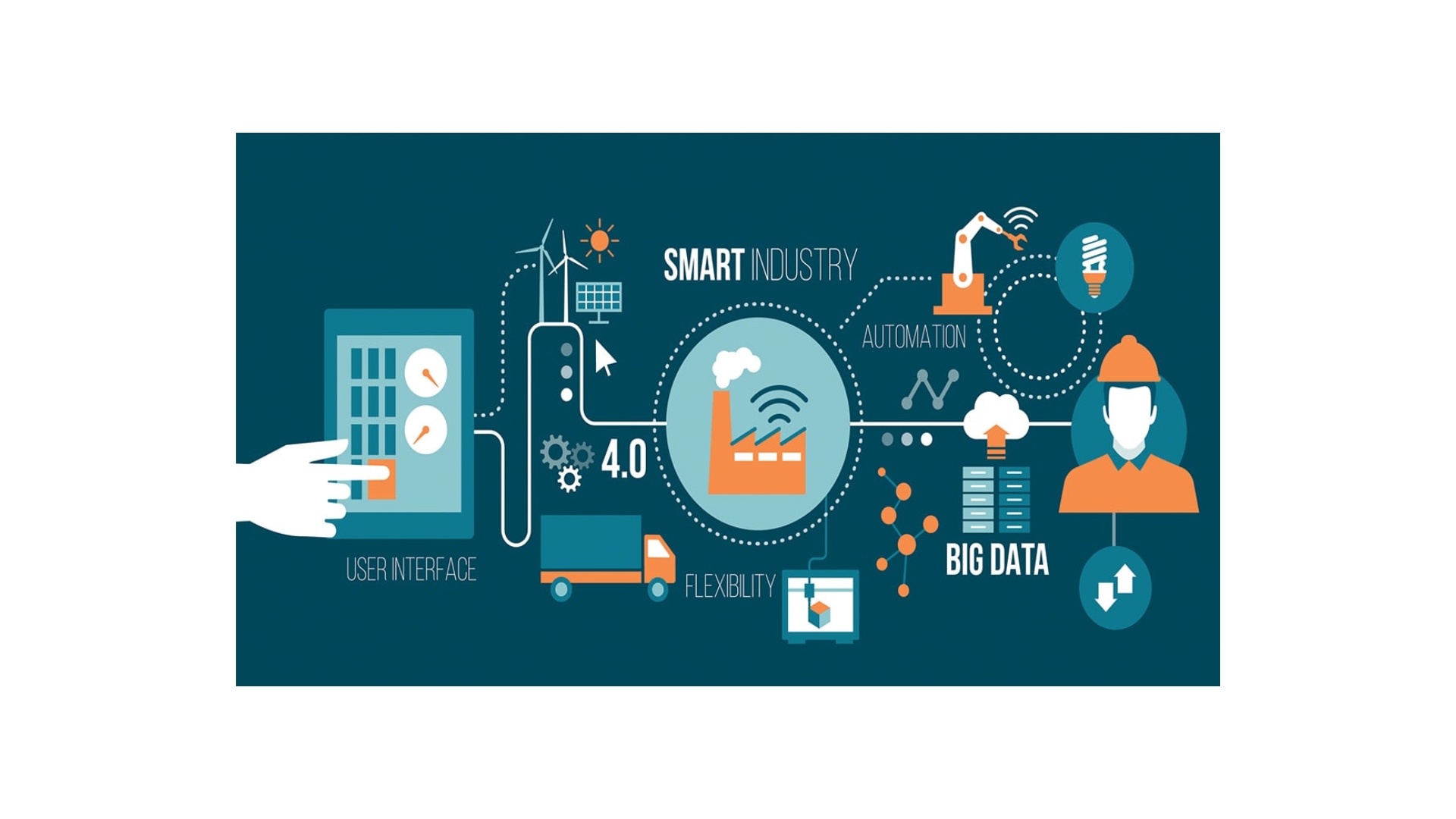

One exciting possibility is the integration of 3D printing with other emerging technologies, such as artificial intelligence (AI) and robotics. AI can optimize the design and construction process, while robotics can assist in automating on-site construction, further enhancing efficiency and reducing human labor. These advancements could lead to fully automated construction sites, where buildings are printed and assembled with minimal human intervention.

Another potential development is the use of 3D printing for large-scale infrastructure projects, such as highways, bridges, and even entire cities. As urbanization continues to increase, the demand for innovative and sustainable construction methods will grow. 3D printing offers a solution that can meet this demand, enabling the rapid development of smart cities with sustainable and resilient infrastructure.

Conclusion

3D printing technology is revolutionizing the construction industry, offering numerous benefits such as reduced construction time, minimized material waste, and increased design flexibility. While there are challenges to overcome, the potential of this technology is undeniable. As it continues to advance, 3D printing is set to play a crucial role in shaping the future of construction, paving the way for more innovative, sustainable, and cost-effective building practices. Whether for affordable housing, commercial projects, or large-scale infrastructure, 3D printing is poised to become a cornerstone of modern construction.